Description – Geologically Speaking

The Cardium is a reservoir rock with stacked successions of silty mudstone, siltstones, and fine to very fine grained sandstones; coarsening upwards to a conglomerate. The sands are informally designated as the Cardium ‘A’ and ‘B’ sandstones, to differentiate the producing zones. The source rock for the Cardium is considered to be the Second White Speckled Shale, although some feel that the First White Speckled Shale and Fish Scales may also have been the source rocks. The Cardium is further sealed above, by inter-bedded mudstones of the Colorado Shale.

The formation top is identified on logs by a distinct resistivity shoulder, after a continuous mudstone interval. The base of the Cardium can also be identified by a resistivity double shoulder, resembling the Russian letter ‘Z’, and often referred to as the ‘Russian Marker’.

Insight – What Happening Now

Experience, new technologies, and experimentation, have come together to re-launch the Pembina Cardium play. The overlooked Cardium ‘A’ tight oil sand of the Cardium formation, has now become a target. The less congested ‘halo’ areas of the field, are being drilled with great success by multiple Operators. Current estimates show the Cardium play lasting for another 50 years, with as little as 17% of the total reserves currently depleted. It is estimated that with current technologies, this may increase to 40% in the next five years.

With the current price of oil becoming unstable, a couple of things have become apparent.

You need to reduce your AFE costs.

Here are a few suggestions:

The first two may sound expensive, or even trivial; but are not when you look at the big picture. Rotary Steerable drilling systems (RSS), coupled with an Optimized drill bit for that particular system, will pay for themselves by increasing ROP’s (rate of penetration), thus reducing drilling hours and costs. RSS drilling systems will produce a smoother hole, with little to no doglegs or troughs. Smoother holes aid in the placement of multi-stage hydraulic fracturing equipment.

Collaborate with your peers, regarding best drilling practices. What RSS drilling system and bits are they using? What Mud System are they using, and are they adding anything to their mud system that has increased ROP, or enabled a longer leg? Have they been using any special handling equipment on the rig that has reduced time? Have they got different strategies regarding drilling of these wells, which has reduced time or added efficiencies?

Secondly, Increase Production?

Longer Horizontal Legs

Now, let us look at the production; which typically varies from well to well. There are a lot of variables to evaluate when drilling these wells, however, some stand out as being more economical to evaluate and understand than others.

Longer horizontal legs have been achieved by the use of Mechanical devices such as the Agitator or Exciter tools. A less expensive option is the use friction reducing glass beads, which are recovered after the drilling operation. Once the rig is set-up and drilling, why not spend the extra time required to drill these longer full target lateral legs, if you stay within your land. While you are at it, why not drill a second leg? The cost may rise by 25-35%, but is still more economical than two separate wells. Second to these, is to increase the number of frac stages for completion of the well. Numerous papers have highlighted the increased production rates where frac stage spacing’s have been shortened. No one to date has reported frac interference, due to a shorter spacing. What has been reported, is an increase in Productivity proportional to the number of fracs placed.

The Hydraulic Fracturing proppant utilized, and the oil production observed, was the old decision making process. Today, Microseismic has scientifically answered a lot of these questions. One Operator reports that Slickwater fracs are the answer, while another reports that by the use of Microseismic, they see why a Foamed Water frac was superior.

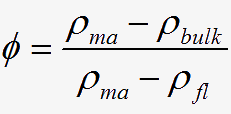

The use of Open Hole Logs plus Microseismic , will allow the Operator to see at what depths the frac got away, and what to look for in future Well Logs. A combination of Logs and Core data, can be used for Petrophysical Analysis in this Unconventional reservoir. Combinations of Log, Core and Seismic datasets will answer a lot of questions, and yield a better understanding going forward.

Last but not least, is the decrease in well spacing. As of October 6-2011, the well density controls for lower quality reservoirs has been amended by the ERCB (Energy Resources Conservation Board), which applies to the current Cardium play. This has been a long time coming, and slow to be adopted. Utilizing decreased spacing, opens another door to increased production from your land.

The Cardium has colossal hydrocarbon storage capacity, which has allowed, and will allow, economic development in the years to come, due to the advancements in oilfield technology.