A density tool, typically ran in open-hole formation evaluation, is used to calculate the total porosity of a given formation. The measurement is derived from the electron density of the formation. From the electron density the bulk density is calculated, which is then used to calculate primary porosity.

What is the primary porosity measurement typically used for?

When paired with a Neutron tool, can aid in the detection of a gas vs. oil bearing formation

Calculate porosity for your Water Saturation calculation

Provide a borehole caliper measurement

How does the Density tool work?

With the use of a Cesium 137 radioactive source, inserted into the tool, the decay process mapped out below shows how Gamma Rays are emitted into the formation.

The steps then begin:

The gamma rays from the Cesium sources are absorbed through interaction with the formation

Gamma rays received back at the scintillation detectors are measured in CPS (counts per second)

The CPS are used to determine the electron density via tool calibration

The electron density is then used to calculate bulk density:

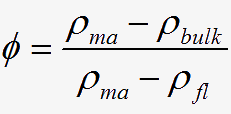

The bulk density is then used to calculate primary porosity:

The medium and long spaced detectors are used in conjunction with each other; this allows the tool to compensate for borehole effects such as mudcake.

Calibration and why it is necessary:

As mentioned above, the calibration is very important to ensure the conversion from CPS to electron density is correct. To do this a spine is created by using two materials of totally different densities, such as concrete and aluminum. From this calibration a density correction is uses if borehole conditions are affecting the density reading.

Note:

Negative density correction should only be seen if the mud is denser than the formation you are reading. An example of this would be coal or really gassy formation. If this is not the case, typically the tool calibration is off and can be re-calibrated and corrected after the logging has been completed.

What 2 things affect the quality of the density data?

Mud system – Certain additives to the muds such as KCL, Barite and Bentonite will either emit or absorb external gamma rays

Logging Speed – Being a statistical tool the quality will be affected by logging speeds

Density Tool Differences

Most open-hole density tools require borehole contact with a pad and use a directional source. The reading can be greatly affected by the orientation of the tool in the borehole and in the horizontal section of a well a dual density usually has to be run to obtain this, which increases the cost of the service.

Cordax's LWT’s density tool, being safely located inside of drill pipe, is omnidirectional. This allows the tool to read 360 degrees around the borehole collecting an average formation density. Also with a third detector the tool is able to calculate a pseudo caliper and density correction similar to that of any conventional borehole contact tool.